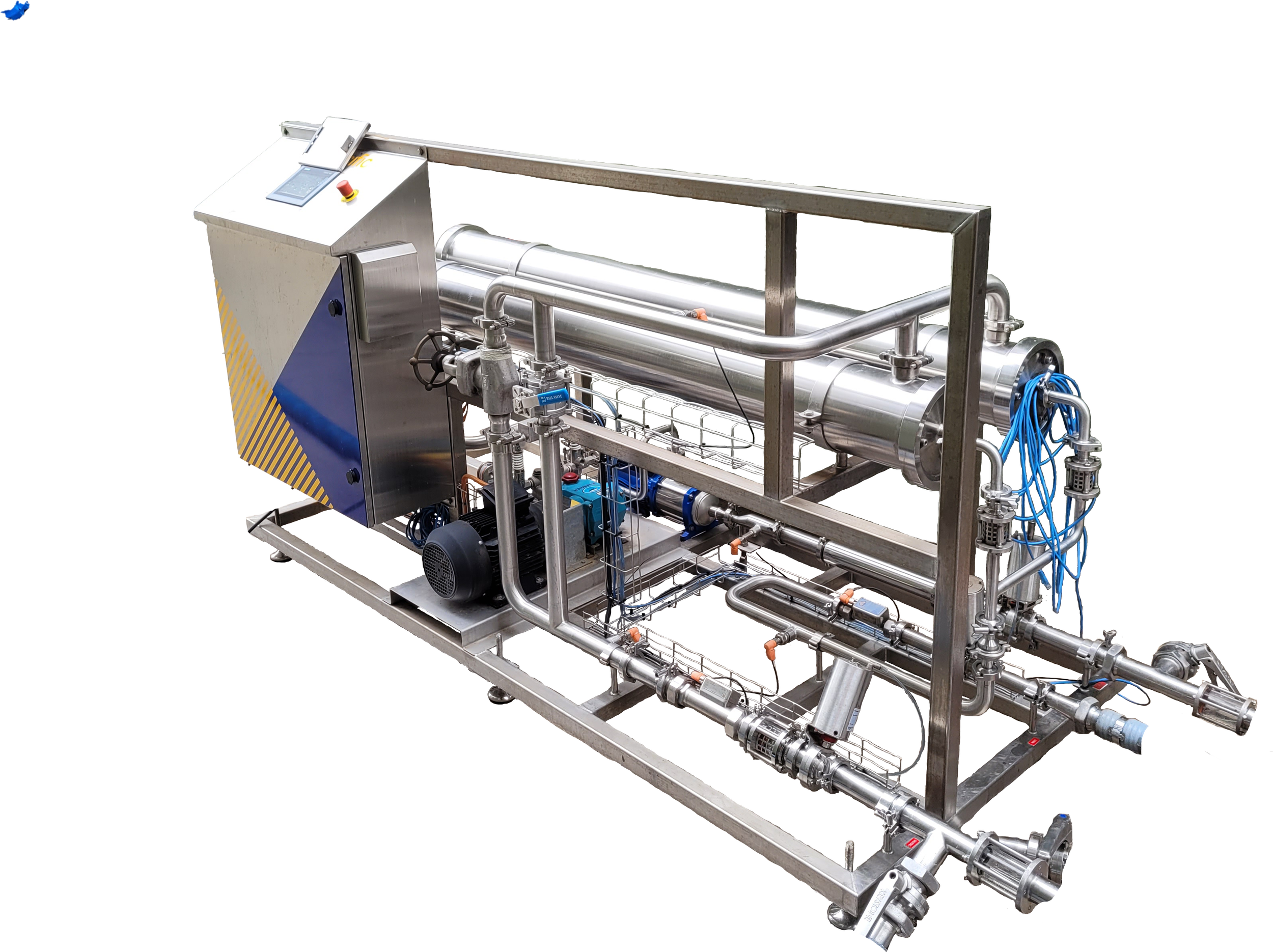

Membrane Separation - 1000 Series

Precision in Every Drop | Membrane Technology That Separates the Best from the Rest

PTI Pacific’s advanced Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO) systems give winemakers precise control over alcohol adjustment, stability, and purity. Enhance wine quality, consistency, and meet market demands with cutting-edge membrane technology—where tradition meets innovation.

Nanofiltration (NF)

✔ Concentration and separation of tannin and polyphenols allowing fine-tuning of wines

✔ Partial dealcoholisation

✔ Water removal and flavor concentration

✔ Decolourisation

✔ Correction of faults such as Brettanomyces and Smoke Taint

Reverse Osmosis (RO)

✔ Removal of volatile acidity

✔ Wine concentration

✔ Acid reduction

✔ Flavour Correction

✔ Correction of faults such as Brettanomyces and Smoke Taint

✔ Dealcoholisation

Ultrafiltration (UF)

✔ Removal of suspended solids

✔ Removal or reduction of proteins and larger macromolecules

✔ Clarification

✔ Decolourisation

✔ Tannin adjustment

✔ Wine clarification and microbial stabilisation

Benefits of using UF, NF and RO Membrane Systems in Winemaking

Volatile Acidity Reduction

Correcting elevated volatile acidity is crucial for wine quality. Using RO you can selectively reduce volatile acidity while retaining the essential components that contribute to the wine’s complexity, ensuring a clean and stable product.

Selective Taint Removal

From smoke taint to Brettanomyces contamination, membrane filtration offers a targeted solution. RO and NF membranes can selectively remove unwanted taints while preserving the wines core characteristics, giving you control over even the most challenging winemaking conditions.

Enhance Aroma and Flavour Intensity

Membrane systems allow you to concentrate specific wine fractions to enhance aromatic intensity and flavour richness, creating wines that stand out in a competitive market. This enables greater customisation and differentiation for premium and boutique wines.

Precision Alcohol Adjustment

Our Reverse Osmosis (RO) systems allow for precise removal of alcohol without compromising the delicate flavour balance. This technology ensures you can create wines with ideal alcohol levels to meet market demands and regional preferences.

Minimise Product Loss

Compared to traditional correction methods, UF, NF and RO membranes enable more efficient separation with minimal wine loss, preserving more of your valuable product during the correction process.

Improved Wine Stability

Nanofiltration (NF) and Ultrafiltration (UF) membranes are highly effective for removing undesirable proteins, ensuring protein stability in your wines. This reduces the risk of haze or sediment formation, keeping your wines clear and visually appealing throughout their shelf life.

Colour and tannin Management

Ultrafiltration (UF) membranes enable the removal of unwanted colour compounds and excess tannins while preserving desirable phenolic qualities. This technology helps refine your wine’s visual appeal and mouthfeel for a more balanced and elegant product.

For more details or to discuss integration, contact our team today.