Pharma, API & Biotech

Cutting-Edge Water Treatment & CIP Solutions for Pharma & Biotech Manufacturing

PTI Pacific is a 100% Australian owned company specialising in the design, engineering and manufacturing of high-quality machines and production solutions for Pharma, Biotech manufacturers and research facilities

CIP Solutions - Economical Automated Cleaning (CIP) solutions from single-tank mobile up to multi-vessel Hot Water and steam sterilising systems for small and medium process facilities

Water Treatment & Purification -PTI Pacific delivers premier non-validated water treatment technologies tailored for the food manufacturing sector. We prioritise water quality for compliance and product excellence, offering solutions from bespoke filtration to advanced and automated purification for all scales of operation, solutions including:

Mains Water Treatment - carbon treatment, particulate (including High-flow) cartridges and bag filters

UV disinfection & Ozonation

Turnkey membrane systems MF, UF, NF and low, high pressure plus industrial and hygienic membrane modules.

Sterilising filtration, including sterile water, tank venting and sterile air/gas

Deaerated Water & Dissolved Gas Management - we offer the most comprehensive selection of technologies for the complete management of dissolved gases in cosmetic products or water.

Talk to us today about our specialist team today about how we can help optimise your production or packaging processes. Contact Us

Our Most Popular Technologies for Pharma and Biotech Manufacturer

800 Series: Precision Filtration for Pharma & Biotech Excellence

In the highly regulated pharmaceutical and biotech industries, purity, consistency, and efficiency are non-negotiable. PTI Pacific’s 800 Series membrane systems set the benchmark for high-performance liquid filtration and separation, ensuring uncompromised product quality, sterility, and regulatory compliance.

Engineered for Critical Filtration Needs

The 800 Series is designed to handle demanding pharmaceutical and biotech applications, delivering:

✔ High-Purity Filtration – Ensures exceptional removal of bacteria, endotoxins, and particulates, meeting stringent industry standards.

✔ Sterile Processing – Enables precise separation in applications such as vaccine production, biologics, APIs (Active Pharmaceutical Ingredients), and cell culture media preparation.

✔ Optimised Process Efficiency – High-flow rates with minimal energy consumption, reducing operational costs while maintaining superior performance.

✔ Scalability & Customisation – Modular design supports various capacities, adapting to both small-batch research facilities and large-scale pharmaceutical manufacturing.

✔ Regulatory Compliance – Designed to meet GMP (Good Manufacturing Practices), FDA, and EU Pharmacopoeia standards, ensuring compliance with global regulations.

Applications in Pharma & Biotech

✔ Sterile Filtration – For injectable drugs, parenterals, and ophthalmic solutions.

✔ Endotoxin Removal – Critical for biologics, ensuring safe and contaminant-free products.

✔ Cell Culture Media Preparation – Removes unwanted particulates while maintaining essential nutrients.

✔ Protein & Enzyme Purification – Enhances the efficacy and stability of biotech formulations.

✔ Solvent & Water Purification – Produces high-purity water for pharmaceutical formulation and CIP (Clean-in-Place) systems.

Why Choose PTI Pacific’s 800 Series?

✔ Proven Technology – Advanced membrane separation for consistent and reliable results.

✔ Cost-Effective Operations – Designed for long service life, reduced waste, and optimised process efficiency.

✔ Seamless Integration – Compatible with existing processing lines for easy implementation.

✔ Industry-Leading Support – Backed by PTI Pacific’s decades of expertise in pharma and biotech solutions.

Elevate your pharmaceutical and biotech manufacturing with the 800 Series—the ultimate solution for precision filtration, sterility, and efficiency.

Precision Dissolved Gas Management for Pharma & Biotech

PTI Pacific delivers advanced membrane technology for precise dissolved gas control in process water, blending, and packaging, ensuring stability, efficacy, and product integrity.

✔ Prevents Oxidation – Removes oxygen to protect active compounds, biologics, and sensitive ingredients from degradation.

✔ Ensures Product Consistency – Eliminates air bubbles for homogeneous formulations in injectable drugs and liquid pharmaceuticals.

✔ Enhances Mixing & Blending – Improves dispersion and stability in emulsions and biologic preparations.

✔ Optimizes Filling & Packaging – Prevents gas-related volume inaccuracies and extends shelf life through inert gas flushing.

✔ Maintains Sterility – Reduces microbial risks with vacuum degassing and controlled gas environments.

PTI Pacific’s dissolved gas management ensures compliance, precision, and superior product quality for pharma and biotech applications.

Hygienic Membrane Solutions for Pharma & Biotech

PTI Pacific provides cutting-edge membrane filtration technology tailored to the strict purity and quality demands of pharmaceutical and biotech industries. Our Reverse Osmosis (RO), Nanofiltration (NF), Ultrafiltration (UF), and Microfiltration (MF) systems ensure the highest standards in product integrity, sterility, and process efficiency.

Reverse Osmosis (RO) – Ultrapure Water for Formulations

RO is a critical step in pharmaceutical and biotech manufacturing, ensuring that all water used in formulations meets ultrapure standards. This process effectively removes contaminants, dissolved solids, bacteria, and pyrogens, ensuring compliance with regulatory standards. Purified water is essential for drug manufacturing, laboratory applications, and injectable solutions.

Nanofiltration (NF) – Selective Separation & Purification

NF provides a highly efficient separation process, ideal for concentrating active pharmaceutical ingredients (APIs) and removing unwanted compounds from natural extracts. This technology is widely used in the purification of amino acids, peptides, and enzyme solutions, maintaining the bioactivity of key ingredients.

Ultrafiltration (UF) – Clarification & Protein Separation

UF plays a crucial role in biotech applications, particularly in protein purification, cell harvesting, and enzyme concentration. It effectively separates large molecules from solvents, ensuring that critical components such as collagen, vaccines, and biologics retain their efficacy. UF is also used for clarification of liquid formulations, removing fine particulates without damaging sensitive ingredients.

Microfiltration (MF) – Cold Sterilization & Bacteria Removal

MF provides a non-thermal sterilization method, removing bacteria, yeast, and particulates from process liquids. This is essential for vaccines, injectable drugs, and sterile ophthalmic solutions, where heat-sensitive ingredients must be preserved. MF is also widely used for air and gas filtration, ensuring contamination-free environments in cleanroom operations.

Ensuring Product Integrity & Compliance

In addition to processing applications, PTI Pacific’s membrane solutions play a vital role in sterile packaging, water treatment, and quality control. These technologies help maintain the highest levels of product safety, extend shelf life, and ensure compliance with global regulatory standards (such as FDA, GMP, and USP).

With over 30 years of expertise, PTI Pacific delivers innovative, reliable, and customized membrane filtration systems for pharma and biotech applications, ensuring efficiency, compliance, and product excellence.

Process Filtration Specialists

With over 30 years of combined process filtration experience, PTI Pacific is your best partner for everything winery filtration. From water filtration including media, carbon and membrane systems, to CIP recovery and ultra-pure water production, PTI Pacific can offer the perfect and most economical solution.

Water Filtration including Carbon, Media

Membrane systems for water and CIP recovery - MF, UF, NF, RO

Sartorius 12-inch and 16-inch Lenticular Filter Modules

Sartorius 400x400 and 600x600 Filter Sheets

Sartorius Premium Pleated Cartridges, Membrane and Capsule Filters

Integrity Testing Devices

Australia’s Largest Range of Stainless Steel Housings

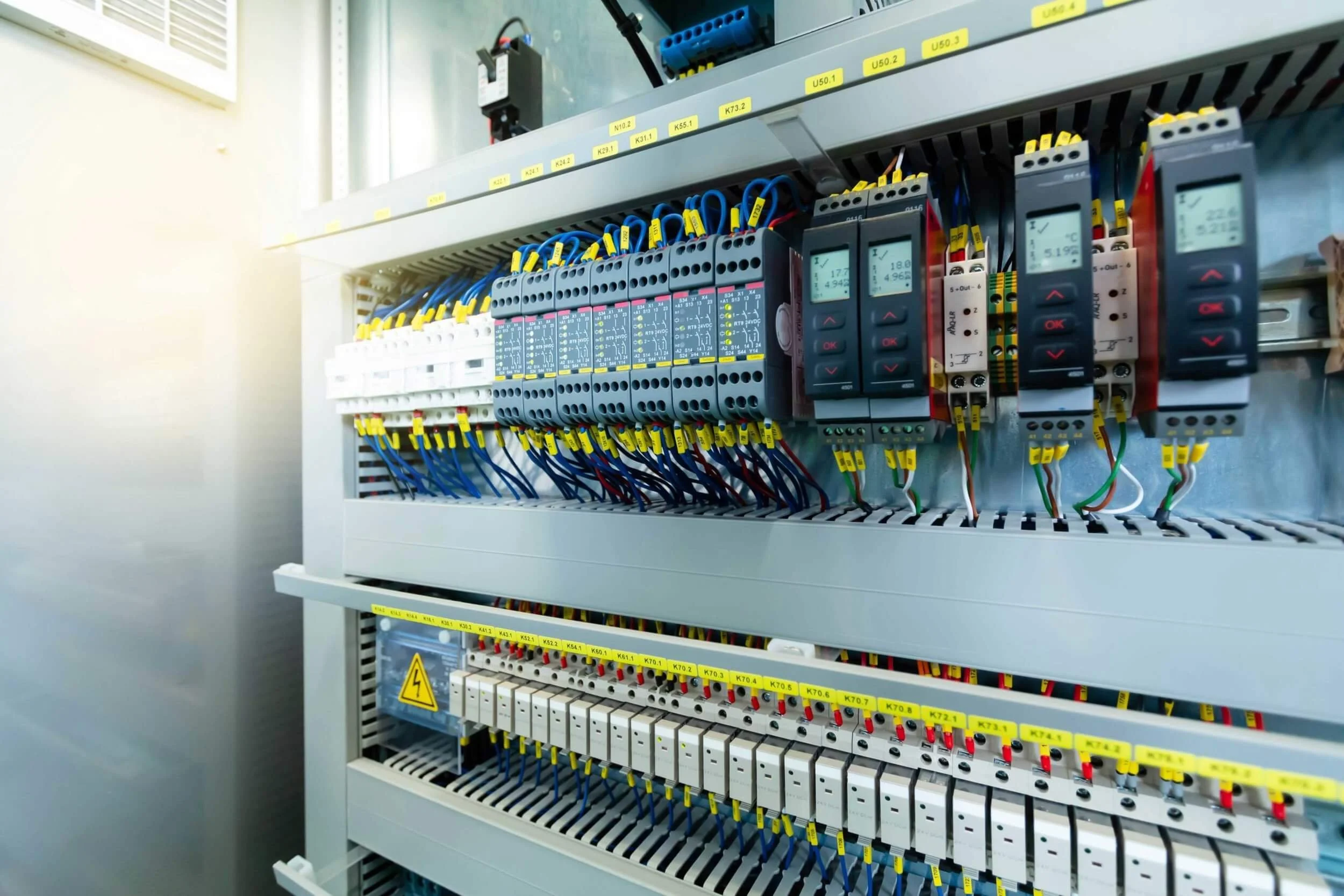

Automation & Mechanical Engineering

PTI Pacific has extensive experience in food production, cooking and processing through to packaging and as such are the perfect partner for your electrical and automation upgrades or projects. As controls specialists we can support your process facility with:

PLC and HMI Programming

Control Panel Building and Installation

Electrical drafting and design

Machine upgrades and automation

Automation and Controls for Pumps, Drives, Valves, Heat-Exchanger, Conveyors etc

Tank Temperature Control Systems

Remote Machine Assess and Telemetry

SCADA Programming and Development

In addition to Electrical and Automation, PTI Pacific can offer a suite of mechanical and project engineering solutions for any Food Manufacturing application. These include:

Machine and factory design, layouts, P&ID and process flow modelling

CAD design including Autocad and Solidworks 2D/3D modelling

Project management for new or upgrade process and packaging lines

Machine sourcing and procurement including importing, installation and commissioning

SOP and operations manual development and writing

Service and preventative maintenance support